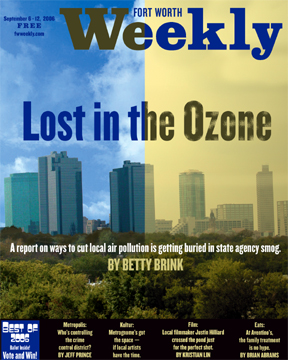

It didn’t come as a big surprise to physician and asthma specialist John Fling that the American Lung Association’s 2006 State of the Air report card for Fort Worth gave the city an F; it’s the same grade the city’s gotten for six years now. Or that the Fort Worth-Dallas metropolitan area is eighth on the association’s list of the worst ozone-polluted cities in the nation. Or that Tarrant ranks as the group’s 11th worst county. Fling is seeing the results every day in the University of North Texas Health Science Center’s neighborhood health clinics where he treats his asthma patients.

“In the last two years, I’ve seen many more cases of asthma than ever before in the summer,” he said. “It has to be the pollution.” The increases are particularly significant, specialists say, because asthma is normally a winter disease. In fact, to Fling and his colleagues, summer isn’t vacation or grass-cutting time — it’s ozone season. “We’re still seeing a big increase [in new childhood cases] during the ozone season, and adults are having more problems as well,” he said. Another anomaly, UNT public health professor Dr. Yu-Shend Lin said, is the rapid onset of the disease that they are seeing. Asthma that develops from other causes takes several years to appear, said Lin, a pollution exposure specialist. “Exposure to ozone causes symptoms very quickly.”

“In the last two years, I’ve seen many more cases of asthma than ever before in the summer,” he said. “It has to be the pollution.” The increases are particularly significant, specialists say, because asthma is normally a winter disease. In fact, to Fling and his colleagues, summer isn’t vacation or grass-cutting time — it’s ozone season. “We’re still seeing a big increase [in new childhood cases] during the ozone season, and adults are having more problems as well,” he said. Another anomaly, UNT public health professor Dr. Yu-Shend Lin said, is the rapid onset of the disease that they are seeing. Asthma that develops from other causes takes several years to appear, said Lin, a pollution exposure specialist. “Exposure to ozone causes symptoms very quickly.”

Healthcare providers, environmental groups, and a growing number of local elected officials believe that the smog that caused a record number of health-alert days this summer is also causing dramatic increases in asthma and other upper respiratory diseases across North Texas. And they believe the smog in turn is being fueled, in no small part, by toxic smokestack emissions from three cement plants in Ellis County, Tarrant’s upwind neighbor. Cement company spokespeople point out correctly that 70 percent of the ozone problems here come from our gasoline-burning vehicles. But the cement plants near Midlothian annually release ozone-making gases equivalent to that from about half a million cars — or almost half of the ozone pollution from all industrial sources.

So a study showing that emissions from the three plants could be cut by 85 percent or more, by installing devices that have been operating in some plants for years, should be big news, right? Wouldn’t that report, which conceivably could affect the cement industry nationwide, get a warm welcome from the environmental agency in a state with major air pollution problems?

No — at least not according to local officials and to the clean-air advocates whose lawsuit brought about the study. Both groups accuse the Texas Commission on Environmental Quality of downplaying the report, minimizing public debate about it, and helping one cement company in an attempt to avoid having to install the recommended anti-pollution devices.

TCEQ officials declined to directly answer Fort Worth Weekly’s questions about its attitude toward the study, which the agency paid for. A commission spokesperson’s response boiled down to reiterating that various pollution control strategies for the Midlothian plant will be considered, and a decision made, at a meeting in December.

The Dallas-Fort Worth kiln study didn’t come about as a result of TCEQ suddenly developing a get-tough enforcement attitude. It was forced on the agency as the result of a lawsuit filed by a tenacious group of citizen activists who have been fighting the polluting plants for years. Two years ago they sued to force the EPA “to do its job” — that is, to enforce the Clean Air Act — and to force state and regional authorities to get serious about cleaning up the region’s air, considered some of the dirtiest in the nation. In an unprecedented settlement with the federal agency last year, the citizens got commitments from the EPA, TCEQ, and local governments to take new, tough steps to bring the region into compliance with EPA clean-air standards by 2010. As part of the settlement, TCEQ agreed to pay for the cement kiln study; the agency also chose the scientists, engineers, and cement experts who conducted it.

The Dallas-Fort Worth kiln study didn’t come about as a result of TCEQ suddenly developing a get-tough enforcement attitude. It was forced on the agency as the result of a lawsuit filed by a tenacious group of citizen activists who have been fighting the polluting plants for years. Two years ago they sued to force the EPA “to do its job” — that is, to enforce the Clean Air Act — and to force state and regional authorities to get serious about cleaning up the region’s air, considered some of the dirtiest in the nation. In an unprecedented settlement with the federal agency last year, the citizens got commitments from the EPA, TCEQ, and local governments to take new, tough steps to bring the region into compliance with EPA clean-air standards by 2010. As part of the settlement, TCEQ agreed to pay for the cement kiln study; the agency also chose the scientists, engineers, and cement experts who conducted it.

The resulting study recommended a pollution-control system that researchers said has been proven to work and is “affordable, available, and must be seriously considered” for the Midlothian plants. The scientists estimated that the system could remove 20 tons of nitrogen oxides — NOx, the main ingredient in ozone — from the air over North Texas each day. That’s nowhere near the 166 tons of NOx per day that the EPA mandate says must be cut within the next four years — but it could be one of the largest jumps toward that goal. This is a “landmark study,” said an SMU chemical engineering professor who has reviewed the report and concurs with its findings. Installing the controls “would go a long way toward cleaning up the air over North Texas,” he said. Despite such comments, there is no indication that TCEQ intends to adopt the study’s findings.

“TCEQ has a dismal record on the cement kilns,” said Dallas Mayor Laura Miller, who is working with a consortium of area mayors to find ways to clean up the region’s air. “Clearly, [the agency] is not interested in forcing the companies to spend the money to make their emissions cleaner.” Jim Schermbeck, co-chair of one of the groups that sued, is more blunt: “TCEQ is deliberately suppressing the report to protect the polluters, just as it’s always done,” he said.

Unless you’ve spent the summer in an air-conditioned subterranean vault, you know this has been North Texas’ hottest and one of the area’s driest years on record. For Fort Worth and Tarrant County, it’s also been the worst air pollution year yet. The ozone alerts started earlier than ever, in May; by Sept. 4, with a month still to go (the ozone “season” ends in October), the area has racked up a record 80 days of harmful ozone levels, based on TCEQ data: 69 “orange” days, meaning that the outside air is dangerous for kids, anyone over age 50, and those with chronic lung diseases; nine “red” days that were bad for everybody; and two “purple” alerts, which means you better hold your breath even stepping out for the mail.

EPA standards set 85 parts per billion as the highest level of ozone that is not likely to trigger asthma or emphysema attacks. This year, ozone levels ranging from 101 to more than 200 ppb were recorded in some parts of Fort Worth.

The Ellis County cement plants are owned by TXI, which also operates a steel plant on the site; Holcim, Inc.; and Ash Grove Cement. They sit in close proximity to one another along the western boundary of the small town of Midlothian, about 10 miles past Fort Worth’s southeastern city limits. Together, according to TCEQ, they dump up to 11,000 tons of NOx into the atmosphere each year, accounting for almost 50 percent of the industrial pollution that is helping turning North Texas’ blue summer skies to brown.

The Ellis County cement plants are owned by TXI, which also operates a steel plant on the site; Holcim, Inc.; and Ash Grove Cement. They sit in close proximity to one another along the western boundary of the small town of Midlothian, about 10 miles past Fort Worth’s southeastern city limits. Together, according to TCEQ, they dump up to 11,000 tons of NOx into the atmosphere each year, accounting for almost 50 percent of the industrial pollution that is helping turning North Texas’ blue summer skies to brown.

TCEQ data show that, on most of Fort Worth’s high-ozone days, the plumes of pollutants blow from the cement plants directly toward Tarrant County. The plumes’ ozone levels increase when they reach Fort Worth’s southeast side and continue to remain high as they wend westward toward Parker County. If the winds are weak, as they often are in the summer, TCEQ spokesperson Andrea Morrow said, the ozone pollutants simply hang over the city in the stagnant air.

Environmental groups say the plants not only threaten the health of their downwind neighbors but also have been the single most important force in blocking officials’ admittedly slow efforts to find ways to bring the region into compliance with EPA’s air quality standards. After four extensions since 1990, the latest deadline for attainment is 2010.

During that time, the plants’ resistance to cleaning up their smokestacks or even admitting that their pollutants are part of the problem has drawn powerful support from an influential Ellis County Republican — U.S. Rep. Joe Barton, head of the House Energy Committee. For years, Barton, who has received millions in campaign dollars from the cement companies, helped keep Ellis from being included in the EPA list of counties that must meet federal air quality standards. That exclusion ended a couple of years ago when the EPA finally put Ellis on its non-attainment list.

Fort Worth State Rep. Lon Burnam is one of those who think the plants have also had a “free regulatory ride” from the state. Several years ago, a Texas clean air plan that called for a 30 percent reduction in NOx emissions from cement plants was scrapped, specifically — according to TCEQ staff e-mails released to the Weekly under an open records request two years ago — to “avoid making TXI too unhappy.” The e-mail exchanges also noted that the agency would “get raked over the coals” by citizens when they discovered that TCEQ was approving a permit for a new plant for Holcim that would double its capacity without forcing the company to use “best available technology” to control pollution, as required by the Texas Clean Air Act.

Fort Worth State Rep. Lon Burnam is one of those who think the plants have also had a “free regulatory ride” from the state. Several years ago, a Texas clean air plan that called for a 30 percent reduction in NOx emissions from cement plants was scrapped, specifically — according to TCEQ staff e-mails released to the Weekly under an open records request two years ago — to “avoid making TXI too unhappy.” The e-mail exchanges also noted that the agency would “get raked over the coals” by citizens when they discovered that TCEQ was approving a permit for a new plant for Holcim that would double its capacity without forcing the company to use “best available technology” to control pollution, as required by the Texas Clean Air Act.

This time around, local elected officials are convinced that the EPA will give no more extensions, meaning they’ve got very little time left to do what needs to be done. Nine counties with a population totaling 6 million — Tarrant, Dallas, Collin, Denton, Ellis, Johnson, Kaufman, Parker, and Rockwall — are now under the EPA gun to clean the region’s air in less than four years “or else.” Or else North Texas will face economic sanctions that could bring progress to a standstill: no more federal highway funds, mass transit dollars, or economic development money for projects like the Trinity River Vision, Fort Worth’s grand plan to turn downtown Fort Worth into Venice West.

The cement kiln study has provided regulators with at least one tool to perform the clean-up — and possibly the most powerful tool they’ve ever had to force smokestack improvements at the kilns. But it was produced only because citizens groups — Downwinders at Risk, Blue Skies Alliance of Duncanville, and several state clean air groups — sued the EPA.

It was the first lawsuit ever filed over dirty air in Texas, said Schermbeck, co-chair of Downwinders, the Midlothian citizens group that’s been fighting the plants for more than 15 years. Although the suit was filed against the EPA, Schermbeck and Wendi Hammond of Blue Skies said its aim was to get all the stakeholders in the area to the table to hammer out a truly workable plan.

Under terms of the agreement, the EPA, TCEQ, and local county governments committed to meet the EPA’s 85 ppb ozone standard by 2010. Included was a requirement that TCEQ conduct a study of the most modern and effective pollution controls for cement plants from around the world and the effect that installation of such controls would have on the region’s smog. Local governments also promised to review cement purchasing policies that would reward the least-polluting cement plants. “The power of the purse,” said Schermbeck. “If the local governments would form a purchasing group that would agree to buy cement only from plants that have the cleanest smokestacks, the Midlothian plants would clean up overnight.” So far, no local government has made such a commitment.

TCEQ however, met its commitment. Since January, it has had in its hands the study done by a group of scientists and engineers from a Cincinnati, Ohio, company called ERG, Inc. Their mandate was to study the feasibility of installing several different pollution control devices on the kilns of all three plants and to document the resulting effects each technology would have on the ozone levels in the Fort Worth-Dallas area. Their findings were consistent for each plant: a state-of-the-art pollution control system called selective catalytic reduction (SCR) would lower the nitrogen oxide emissions from those plants by at least 80 to 85 percent. The system works much like the catalytic converter in an automobile, by changing NOx into harmless nitrogen gas and water vapors. It doesn’t produce “corrosive byproducts,” the report stated, and wastewaters from the scrubbers are rich in nitrates that can be used as fertilizer for erosion-control landscaping at the cement plants.

SCR was the most expensive of the systems tested, according to the report, with a price tag of $5 million to $11 million in capital costs per plant — about twice as expensive as the next most effective system. Still, the authors concluded, for cement factories turning out a million or more tons of Portland cement a year, as the Midlothian plants do, SCR is affordable. Documents show it has been proven effective in more than 200 coal-fired power plants in this country and 18 cement plants in Europe, with reductions in nitrogen oxides as high as 90 percent. SCR, the researchers wrote, “must be seriously considered” for the Midlothian plants.

“SCR alone is not a silver bullet,” Hammond said. “There are still the cars to deal with, but SCR would play a significant role in getting the Dallas-Fort Worth air cleaned up.”

“SCR alone is not a silver bullet,” Hammond said. “There are still the cars to deal with, but SCR would play a significant role in getting the Dallas-Fort Worth air cleaned up.”

Al Armendariz, a chemical engineer at SMU’s graduate school of engineering, is an advisor to the groups who brought the lawsuit and is currently observing the cement operations at the Holcim plant as part of the agreement. “I have had complete access to plant records. The staff has been completely open,” he said, and he has seen enough of the cement-making process to know that “SCR technology could be made to work” in the two dry kilns at Holcim. The plant produces more than one million tons of clinker — the basic ingredient of Portland cement — annually. The other plants have not opened their doors to Armendariz. Still, he is convinced from what he’s seen at Holcim that the technology will work at the other plants, just as the authors of the study concluded.

Armendariz agrees that SCR would be just one step in the now almost desperate rush by area leaders to find ways to get the region’s air up to EPA standards in four years. “But it is the right step, and it is not an insignificant step,” he said. Installing the pollution controls on the cement kilns would reduce the plants’ emissions from around 10,000 tons a year to a little more than 2,000, he said.

The environmental staff he works with at Holcim “all seem like good, reasonable people” who want to clean up the air, Armendariz said. “However, they have legitimate concerns that if they spend the money to retrofit and their competitors don’t, they will lose money. If something like SCR is to be done, it will have to be done by all the companies. No one is going to volunteer.”

And that means the decision is back in TCEQ’s court. The only way SCR is going to be installed in the kilns of Midlothian, Armendariz believes, is if it is forced on the plants by federal and state regulators.

The plants and the Portland Cement Association, fearing just such a regulatory attempt, have mounted a campaign to discredit the report, putting out claims that it is inaccurate and dismissing the European experience with SCR as unreliable and unworkable in U. S. plants

The last thing the cement plant group wants, Schermbeck said, is to have the state mandate installation of SCR systems for its plants and set a precedent that other states might then have to follow. “That’s why what happens here in Texas is so important,” he said. “It will have impacts all across the country.”

In May, representatives from the Midlothian plants and PCA traveled, uninvited, to a German cement plant outside of Nuremberg that was cited in the report as having a successful SCR installation that had reduced NOx emissions by more than 85 percent. But at the time of the unannounced visit, the plant was testing another system as a back-up. Called “Selective Non-Catalytic Reduction,” that system also was analyzed by the authors of the TCEQ study and found wanting, with NOx reductions of no more than 50 percent. Nonetheless, the cement industry group sent TCEQ a negative report on the German plant, stating that the German plant manager said that “SCR is no longer operational.” The letter indicated that SCR was not reliable and that the cheaper non-catalytic system had been found to work just as well.

In May, representatives from the Midlothian plants and PCA traveled, uninvited, to a German cement plant outside of Nuremberg that was cited in the report as having a successful SCR installation that had reduced NOx emissions by more than 85 percent. But at the time of the unannounced visit, the plant was testing another system as a back-up. Called “Selective Non-Catalytic Reduction,” that system also was analyzed by the authors of the TCEQ study and found wanting, with NOx reductions of no more than 50 percent. Nonetheless, the cement industry group sent TCEQ a negative report on the German plant, stating that the German plant manager said that “SCR is no longer operational.” The letter indicated that SCR was not reliable and that the cheaper non-catalytic system had been found to work just as well.

The facts were misrepresented, said Armendariz, who has been in contact with those involved. “The plant manager spoke no English, and there were obvious misunderstandings. He was in fact very proud of SCR,” and there are no plans to shelve it.

The industry is working the political system hard, said Schermbeck, trying to stave off efforts by clean air advocates and elected officials to pressure TCEQ into funding even a pilot SCR program at one of the Midlothian plants. The obvious reason is money. While the non-catalytic process is the cheaper of the two systems by about half, it also cuts only about half the emissions of SCR.

EPA director Richard Greene and members of the North Texas Council of Governments clean air steering committee, which includes county judges from Dallas and Collin counties and representatives from citizens groups, want the agency to test SCR in at least one of the plants in real-world conditions before TCEQ issues any more permits for less-efficient pollution-control technologies.

Schermbeck and his colleagues are convinced, he said, that TCEQ is going along with the cement companies’ plan to “sabotage this landmark report by keeping it out of the public discussion with stakeholders in this region” while the cement companies work with TCEQ to get permits for cheaper but less-effective NOx-reducing systems.

In December, when the first draft report was ready, TCEQ made it available to cement plant executives but not the members of the clean air steering committee. The reason, the group was told, was to “protect proprietary information.”

Then in June, after the final draft was published, Schermbeck attended a public meeting in Irving called by TCEQ to talk to local officials, the clean air steering committee, and members of the public about the report and the effect of the kilns on the region’s air. “The meeting was taken over by the agency bureaucrats and two industry reps, who didn’t mention the report until near the end of the meeting, and then just in passing, in spite of many of us who were there asking about it,” Schermbeck said. “Our questions were ignored.” A report of the meeting on the agency’s web site, he said, doesn’t mention the kiln study or the criticisms of those in attendance who questioned the lack of discussion about it. But it did devote a lot of space to the statements of the two cement industry reps. “It was incredible,” he said. “A meeting that was called specifically to discuss the kiln report ignored it completely.” The Weekly’s questions to TCEQ about the meeting went unanswered.

Now, Schermbeck said, documents obtained by Downwinders under the Texas Open Records Act indicate that the agency is going to let TXI fast-track a permit that will allow the plant to burn tires and install the less expensive non-catalytic control system.

Now, Schermbeck said, documents obtained by Downwinders under the Texas Open Records Act indicate that the agency is going to let TXI fast-track a permit that will allow the plant to burn tires and install the less expensive non-catalytic control system.

“Unfortunately, instead of choosing to join the EPA, local officials, and citizens groups in organizing a pilot test of an SCR system promising 80 percent-plus removal,” Schermbeck said, “TXI unilaterally opts for an alternative that is approximately half as effective as SCR and that has no hope of reducing NOx levels in their Midlothian wet kilns.”

On June 29, TXI requested a permit from TCEQ — without public hearings — that would allow it to test the cheaper non-catalytic pollution control system on one of its kilns. TXI wrote that the system would reduce nitrogen oxides by 10 to 30 percent. “This would have been progress 10 years ago,” Schermbeck said. “Now it’s a transparent attempt to derail the application of the more effective, groundbreaking SCR.”

Asked to comment on the charge that their agency is helping TXI bypass the most effective pollution-control system, TCEQ officials first asked for questions in writing and then gave no clear answers to them.

The agency provided only a vague response by e-mail, noting that “proposals for control strategies, including SCR and SNCR, to address the DFW non-attainment area will go before the commission in December.” TCEQ public information staffer Andrea Morrow wrote, “The commission will make the decision about what requirements [for pollution controls] will be proposed at that time.”

When Downwinders co-chairman Becky Bornhorst was picking up documents released to her group under the open records act, she said an agency staffer whom she knows well “quietly told me that TXI was ‘trying to beat the calendar’ with its permit request.”

TXI’s strategy is obvious, said Schermbeck. “If a permit for another type of pollution control has been approved, there is no way TCEQ is going to force TXI to switch to SCR no matter what the local officials want.”

TXI attorney Al Axe confirmed to the Weekly that the plant has asked for the permit to install the non-catalytic technology. In addition, he said, TXI is seeking a permit to burn tires in another of its kilns. “This technology is safe,” Axe said, and “has been proven to reduce nitrogen emissions by as much as 30 percent.”

“Only in the minds of cement executives is 30 percent better than 85 percent,” Schermbeck said, with a humorless laugh.

TCEQ rules provide that if there is a tie vote on a permit, it is denied. The TCEQ board was down to two commissioners, meaning a tie vote might be a possibility. But recently Gov. Rick Perry filled the third slot on the commission. Schermbeck is sure that means the cement company will get its permit. “There is no way this governor would have appointed someone without knowing how he’s going to vote on a TXI request,” Schermbeck said. “That company, after all, has put more than $150,000 into Perry’s campaigns.”

Perry spokesperson Kathy Walt said that the governor “never gets involved in TCEQ issues. He leaves decisions about particular cases up to the regulators. He expects them to enforce the environmental laws of the state.”

Don’t believe it, said Austin Public Citizen head Tom “Smitty” Smith, whose group was a party to the Downwinders’ lawsuit. “The power and influence of this industry [cement] has gotten the sweetest ride of any in the state with Perry’s backing. But then, Perry has never met a polluter he didn’t like.”

Midlothian, whose economy is heavily dependent on the three plants, touts itself as the “Cement and Steel Capital of Texas.” In all, the 10 kilns operated there by the three companies produce almost 6 million tons of Portland cement a year, pumping $245 million into the town’s economy, including an annual payroll of $22 million.

But there’s a dark side to that shiny coin. Of the 223 known industrial sources of air pollution in the region, the Midlothian cement plants are the three largest contributors.

“We are committed to cleaning up the air,” said Axe, the Austin attorney for TXI and the Portland Cement Association.

In addition to asking state permission to install the non-catalytic pollution control system in two of its older kilns, Axe said, the company will also ask TCEQ to approve a plan to start burning tires in another kiln. Tire burning reduces NOx, he said, because the process uses a secondary combustion to burn the tires, which reduces the excess heat, a major contributor to the formation of NOx. The company is already burning hazardous waste in its kilns, and if the state approves its tire-burning permit, it will join the other two plants that already use tires for fuel. A reduction in NOx emissions may not be the only reason TXI applied for the permit. As part of the settlement of an old lawsuit between TXI and the state, TXI “is eligible for a $1 million grant to retrofit their kilns to burn whole tires,” Morrow, the TCEQ spokeswoman, wrote.

Burning tires and hazardous wastes in the kilns releases more than nitrogen oxides into the air — those fuels also emit mercury, benzene, chromium, lead, and scores of other toxins that cause cancer, birth defects, auto-immune-deficiency diseases, and mental retardation.

Axe said the cement plant emissions are only minor contributors to the area’s bad air. “If all three plants shut down tomorrow, the air quality in Dallas and Fort Worth would not improve enough to be measurable,” he said.

The kiln report says otherwise, but Axe dismisses the report as “not accurate.” As for the dramatic reductions in nitrogen oxides cited at one German cement plant and the coal-fired plants here, Axe said “the kilns are different in Germany” and “you can’t compare a cement plant operation to those of an electric plant.”

While the debate goes on among industry reps, state regulators, and elected officials over how to best bring North Texas into compliance with EPA ozone standards, healthcare providers like Fling continue to do what they’ve been doing every day for years: treat the victims of the region’s decades-long failure to clean up its air. In Tarrant County, more than 37,000 children have asthma, according to the American Lung Association. Data from Fort Worth health department surveys show that a disproportionate number of asthmatic kids live in predominantly poor minority neighborhoods.

“It’s a significant problem for our children that’s been too long ignored,” said Tarrant County Commissioner Roy Brooks, another person who sees the results first-hand in the neighborhoods he represents and where he grew up. Brooks has worked for years to get more public health clinics established in low-income neighborhoods and to call attention to the high number of asthma cases in those communities. Many of the neighborhoods with the largest population of asthmatic children are on the city’s far southeast side, a fact that Brooks thinks has more to do with location and wind direction than the traditional asthma triggers such as viruses, allergies, and indoor air pollution. “Those neighborhoods take direct hits from the pollution from the cement plants,” he said, when the wind is blowing from the east-southeast toward the city.

The dramatic rise in the debilitating and often deadly lung disease here and across the country is well documented and is a public health crisis of enormous significance, Fling and Brooks said. There is no doubt in their minds that ozone and other airborne pollutants from industrial sources such as the cement plants are playing a major role in the crisis. “Only a fool would think otherwise,” Brooks said.

But no matter how dedicated health- care providers are to treating the disease, the crisis here will only continue to get worse, Fling said, until the environmental regulators in Austin begin to care more about the health of the citizens than the bottom-line health of the polluters.

“The cost of doing nothing,” he said, “is immeasurable.”

You can reach Betty Brink at bcbrink@earthlink.net.

[…] Lost in the Ozone – Posted September 6, 2006 by Betty Brink in News […]